In Formula One racing, the speed on the field is exciting, while in the field, engineers of each team need to deliver products in the shortest time to keep themselves competitive. Through honlitech's caddoctor solution, Renault's product development process is more efficient, and engineers can spare more time for product innovation.

In the traditional R & D process of Renault team, engineers need fast and reliable local method to convert various CAD and CAE format data. Taking NX to CATIA as an example, the general method is to convert NX data to step or IGES format, and then convert the general format to CATIA format, but the biggest problem of this method is that the generated geometry may contain defects and Flaws, such as missing faces and open edges, can cause digital to analog quality problems. This means that engineers have to re model to ensure that all geometric information of the part will not be lost, but this process often takes days or even weeks.

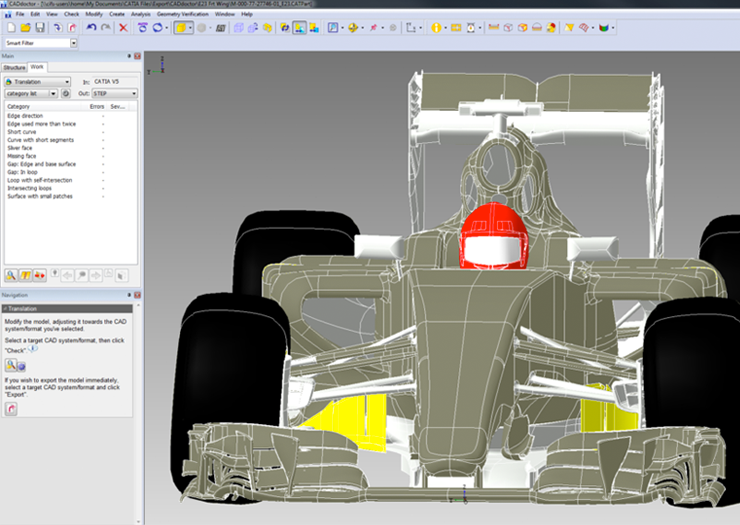

The honlitech's caddoctor solution can solve this problem well. Its greatest value lies in the conversion of CAD data in various formats with the highest efficiency, speed, stability and quality. It can also optimize the product data quality (PDQ) product data quality of Renault team and complete the repair of geometric model in a short time.

After Renault purchased the team from Benetton, its engineers met the problem of converting a complete gearbox model to CATIA format. At that time, engineers spent a lot of time and energy to solve the problem of geometric information loss in the conversion process. After using caddoctor, engineers simply handled the problem for several hours, and the problem was solved. Now, in the whole development cycle of Renault team from concept design to production, engineers choose caddoctor as a powerful assistant of CATIA, its main CAD tool; in the stage of aerodynamic concept, caddoctor can send data to external partners in general industry standard format (step, IGES, Parasolid). In addition, honlitech's asfalis solution can make the whole process of data transformation and repair automatically in the backstage server. All the engineers have to do is submit tasks on the web side, which also makes it easy for Renault team cam users to transfer CAD data to some new machine controllers for NC programming. Asfalis is a good way to make up for the lack of caddoctor interactive transformation and repair data.